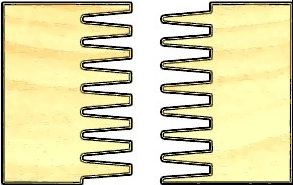

Firstly, we have to remember what a finger joint is: a woodworking end-joint made by cutting a set of complementary, interlocking profiles in two pieces of wood, which are then glued, in order to extend them. The cross-section of the joint is similar to the interlocking of fingers between two hands, which is the origin of the name “finger joint”. The sides of each profile increases significantly the surface area for gluing, resulting in a strong bond.

The finger joint is not something new in the wood industry: it’s been used for decades. First written records report finger joints being used in the wood steering wheels in the very beginning of automotive industry.

Edge gluing is an effective way to create a large and stable panel of wood with a seamless and solid appearance once it is difficult to get wide lumber as trees usually do not grow so big.

Finger joint Pine Panel

Finger joint pine panels are single-layer panels made of pieces of pine glued end to end or side by side. Because the finished panels are strong and keep their shape well, they are ideal for high quality furniture and interior decoration such as staircases and window sills.

This product is very popular due to its cost is less than the solid pine. Although this type of product is not recommended to apply stain or varnish as the joints are visible, you can use it for painted applications. It could also be used as secondary wood in a project where you only want to see the better grade of wood. You can also use it to build jigs and forms.

Video – Finger joint pine panel